There are a lot of extruder drive methods kicking about at the moment, so I decided to evaluate a few by measuring the amount of force they can apply to the plastic before it slips. Rather than build complete extruders, I just made mock ups of the final drive and measured the force they could apply to a spring balance.

My first test was using a splined shaft as a minimalist pinch wheel. This was inspired by Adrian Bowyer's

knurled design. I wanted to try it because you can get steppers with splined shafts, so it would be a ready made solution rather than needing a knurling tool and a lathe. I used a 4mm splined shaft that I had lying around. Being that small means the torque required to turn it is quite modest.

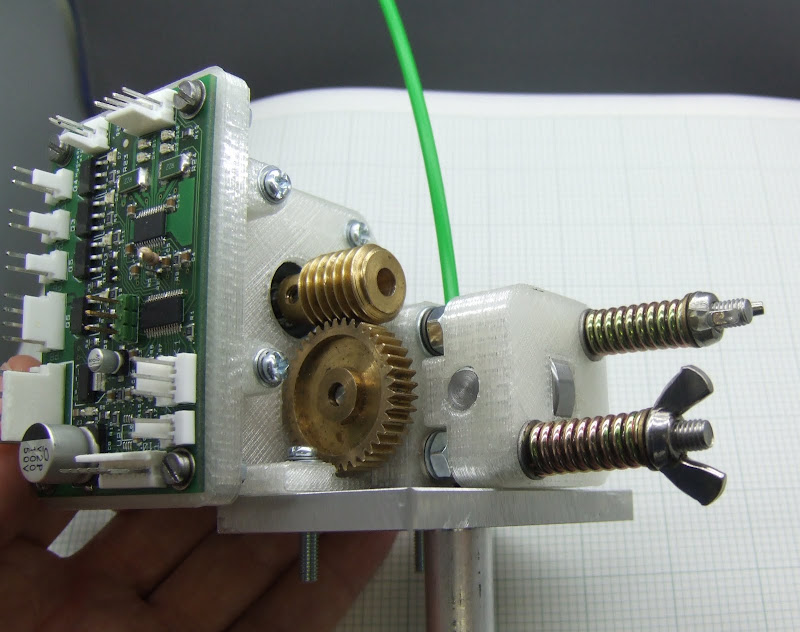

I mounted it between ball bearings, which were a press fit into a plastic housing: -

The Meccano gear is just acting as a knob at the moment. I pressed the filament onto it using a skate bearing acting as a roller.

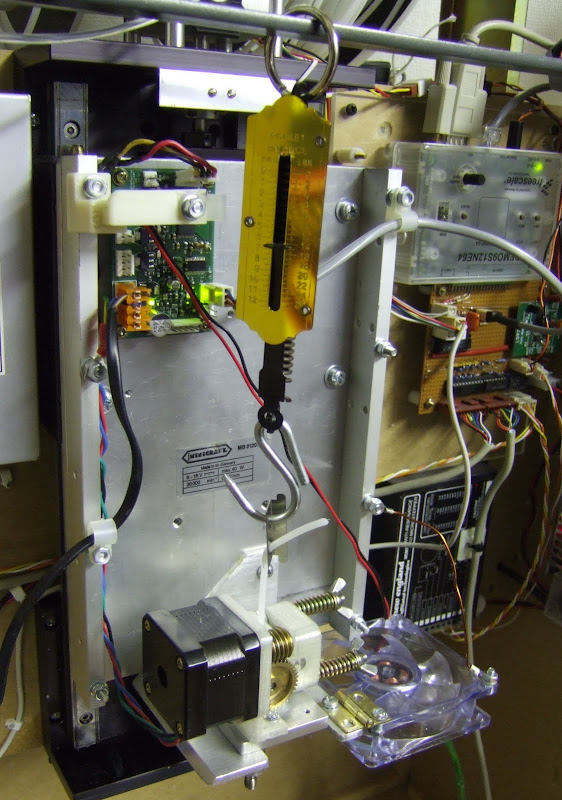

This is my sophisticated test set-up: -

I wind the knob by hand until the filament slips and observe the maximum force for each type of plastic. I noted that tightening the screws past the point where the splines are fully sunk into the filament does not increase grip, it just flattens the plastic more and needs more torque.

The results were: -

| PCL | 2.5Kg |

| HDPE | 3Kg |

| ABS | 5Kg |

| PLA | 7.5Kg |

Not surprisingly the grip gets better with the harder plastics. Unfortunately PCL and HDPE need quite a lot of force to extrude, so this drive method is not really good enough for them. A larger diameter shaft should give more grip due to a larger contact area and possibly deeper splines.

The next method I tried was Zach's

pinch wheel drive using a square tooth timing pulley.

This needs much higher torque, but gives a much better grip, particularly with the softer plastics. As you might expect the torque is very uneven as the pulley moves from tooth to gap to tooth.

With HDPE, it pulled out of the chuck before slipping, so I switched to an alternative connection to the spring balance.

The results were: -

| PCL | 4Kg |

| HDPE | 10Kg |

| ABS | 8.5Kg |

| PLA | >8Kg |

PLA slipped from the chuck and snapped when using the alternative coupling, so the true figure is probably higher, but it far exceeds the force needed to extrude PLA anyway.

HDPE has shot up the ranking because although it is quite soft and very slippery, if you

can get a grip on it, then it is very tough.

Only PCL is marginal compared to the force needed to extrude it.

Zach uses a bigger opposing wheel, so maybe that would give a bit more contact area.

The next thing I tried was the original screw feed design, to get a benchmark, as that is what I have been using so far. It can feed all four plastics reliably, the only problems I have had with it are that the bearings wear out after 100's of hours of use, easy to fix by using ball bearings.

The implementation I used for the test has phosphor bronze bearings and a stainless steel screw. Rather than use threaded rod and try to fasten a nut on the end, I used a hex head bolt. Long ones don't come with enough thread, but you have to run a die over it anyway to sharpen the thread.

It is very hard work tapping stainless steel. For my first attempt I made the mistake of turning the top bearing land before tapping, so that I didn't mar the thread in the lathe chuck. Even though I made the land 3.5mm diameter rather than 3mm, the torque required to tap it actually twisted the shaft where it was turned down. My nice polished bearing surface became a dull and wrinkly spiral!

The other half of the drive is made from HDPE. I think this is a big factor in making it work well as the HDPE is very slippery and doesn't seem to wear much.

A self tapping screw secures the PTFE insulator in the clamp.

The other crucial modification is to angle the screw so it bites gradually at the bottom by spacing the top with two M3 washers and only having two very strong springs at the bottom. Here it is under test: -

The grip was too high for my chuck, and the coupling shown above kept snapping PLA, so I made a brass coupling.

This has a 5mm bore that narrows to a 3mm hole in the bottom. I melt the end of the filament to a blob and feed it through the top.

The results were: -

| PCL | 9Kg |

| HDPE | >12Kg |

| ABS | >12Kg |

| PLA | >12Kg |

My spring balance has a maximum reading of 12Kg.

So the screw drive has dramatically more pulling power. It is however, very mechanically inefficient. A lot of torque is wasted by the friction cutting the thread. This can be reduced by shortening the amount of thread engaged. I plan to try it with an opposing roller instead of the HDPE filament guide.

The threaded drive does do more damage to the filament, but the only downside of that seems to be that some dust is produced. The lower filament has been chewed by the timing pulley.

Two other drive methods I plan to try are a knurled shaft and Andy Kirby's

worm wheel. That looks like it might have similar grip to a thread, but without as much friction. A lot harder to make though.